油田热媒加热炉: 负荷供热能力50----1500×104kcal/h, 导热油的出口温度:≤350℃

Oilfield heat medium heating furnace: load heating capacity 50-1500 × 104kcal/h, outlet temperature of heat transfer oil: ≤ 350 ℃

主要用于油气集输系统过程中,将原油、天然气等加热到工艺要求的温度,以便进行输送、沉降、分离、脱水和初加工。

Mainly used in oil and gas gathering and transportation systems to heat crude oil, natural gas, etc. to the required temperature for transportation, settling, separation, dehydration, and initial processing.

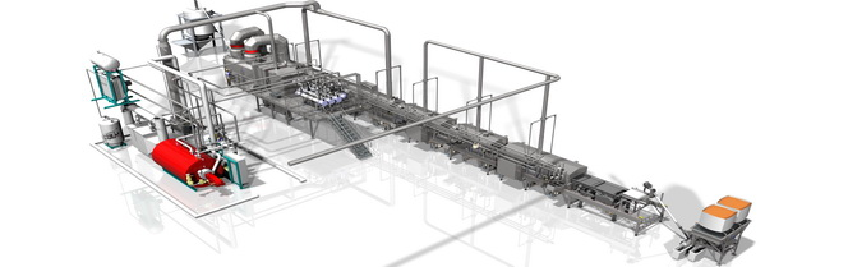

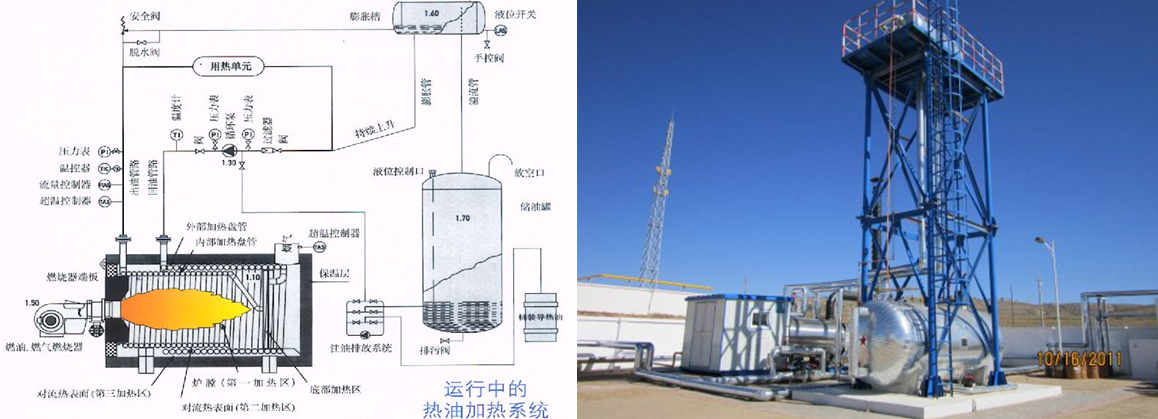

热媒加热系统主要由热媒加热炉(有机热载体炉)、储油罐、膨胀罐、循环泵、注油泵、氮封系统、控制系统等组成,且各自分别成撬供货。

The heat medium heating system mainly consists of a heat medium heating furnace (organic heat carrier furnace), an oil storage tank, an expansion tank, a circulation pump, an oil injection pump, a nitrogen sealing system, a control system, etc., and they are supplied separately.

热媒加热炉采用三烟道半湿背式设计。热量通过燃烧器在炉膛内燃烧并以辐射热和对流换热的方式传递给热媒,载热热媒通过循环系统运送到热用户,在热用户换热卸载后再循环回到热媒炉加热;如此往复以热媒为载体实现热量传递,膨胀罐、循环泵及控制系统为系统不可缺少的辅助设备。

The heat medium heating furnace adopts a three flue semi wet back design. Heat is burned in the furnace through a burner and transferred to the heat medium through radiative heat and convective heat exchange. The heat carrying heat medium is transported to the heat user through a circulation system and is recycled back to the heat medium furnace for heating after the heat user unloads the heat exchange; By using heat medium as a carrier to achieve heat transfer, the expansion tank, circulation pump, and control system are indispensable auxiliary equipment in the system.

A、主要性能特点:

A、 Main performance characteristics:

1、采用炉体橇、循环泵橇、膨胀罐钢架橇、注油泵橇、氮封橇五大橇块模式供货。并接受用户的特殊订货。

1. We supply using five main sled modes: furnace body sled, circulation pump sled, expansion tank steel frame sled, oil injection pump sled, and nitrogen sealing sled. And accept special orders from users.

2、高静压的泵入口压力设计,脱水效果快,系统运行性大大增强。

2. High static pressure pump inlet pressure design, fast dehydration effect, greatly enhances system operation.

3、专利设计的热备用循环泵功能,在极低环境中可以迅速顺利启动投入运行。

3. The patented hot standby circulation pump function can be quickly and smoothly started and put into operation in extremely low environments.

4、热媒炉盘管采用弹簧式设计,有效吸收热膨胀,防止冷热膨胀导致的炉墙或盘管损坏,保证盘管的安全。

4. The heat medium furnace coil adopts a spring type design, effectively absorbing thermal expansion, preventing damage to the furnace wall or coil caused by cold and hot expansion, and ensuring the safety of the coil.

5、最优的流程设计,排气迅速有效,整个系统无需再设计排气口,投运顺利快捷。

5. Optimal process design, rapid and effective exhaust, no need to design exhaust ports for the entire system, smooth and fast operation.

6、关键保护仪表为进口仪表,德国品质。

6. The key protective instruments are imported instruments of German quality.

7、出口温度高,100~320℃,满足众多用户的需要。

7. The export temperature is high, ranging from 100 to 320 ℃, meeting the needs of many users.

8、成熟稳定的pid控制参数,系统输出温度温度波动小,小于±1℃。

8. Mature and stable PID control parameters, with minimal temperature fluctuations in the system output, less than ± 1 ℃.

9、热媒炉前后墙为开启式结构,便于炉管清洗和维护。

9. The front and rear walls of the heat medium furnace are of an open structure, which facilitates the cleaning and maintenance of the furnace tubes.

10、 燃料系统广泛,渣油、重油、轻油、天然气、城市煤气以及化工工艺废气。

10. The fuel system is extensive, including residual oil, heavy oil, light oil, natural gas, city gas, and chemical process waste gas.

11、 提供稳定的低压高温热源,且能实现一套系统提供多温位热源。

11. Provide stable low-pressure and high-temperature heat sources, and enable a system to provide multi temperature heat sources.

12、 系统热负荷自动调节、连续运行;系统全自动运行无人值守。

12. Automatic adjustment of system heat load and continuous operation; The system runs fully automatically without human supervision.

13、 系统介质实现自动补偿、自动调节。

13. The system media achieves automatic compensation and adjustment.

14、 实现远程的DCS控制。

14. Implement remote DCS control.

中国常州市上能锅炉有限公司联系方式

Contact information of Changzhou Shangneng Boiler Co., Ltd., China

联系人:芮亚平

Contact person: Rui Yaping

手机:+8613815029577

Mobile:+8613815029577

微信号:13815029577

WeChat ID: 13815029577

邮箱:czjnguolu@163.com

Email: czjnguolu@163.com

工厂地址:常州市新北区黄河西路与尚德路交叉路口向南160米处

Factory address: 160 meters south of the intersection of Huanghe West Road and Shangde Road in Xinbei District, Changzhou City

开户行:中国工商银行常州钟楼支行

Opening Bank: Industrial and Commercial Bank of China Changzhou Zhonglou Branch

美元帐号:1105020509714031781

USD account: 1105020509714031781

上一篇:没有了!

下一篇:油田水浴式加热炉