本公司专业制造燃油燃气水浴式加热炉,专为加热天然气或原油用的无压热水锅炉,是为满足油田特殊需要而设计的一种专用加热设备,主要用于油气集输系统过程中,将原油、天然气等加热到工艺要求的温度,以便进行输送、沉降、分离、脱水和初加工。

Our company specializes in manufacturing fuel gas water bath heating furnaces, which are pressure free hot water boilers designed specifically for heating natural gas or crude oil. They are a specialized heating equipment designed to meet the special needs of oil fields, mainly used in the process of oil and gas gathering and transportation systems to heat crude oil, natural gas, etc. to the required temperature for transportation, settling, separation, dehydration, and initial processing.

详细说明:负荷范围: 1000 kW (80万大卡/h) 至10000 kW (860万大卡/h) 燃料:天然气,LPG,工艺气体,轻油(柴油),重油,原油。

Detailed description: Load range: 1000 kW (800000 kcal/h) to 10000 kW (8.6 million kcal/h) Fuel: natural gas, LPG, Process gases, light oil (diesel), heavy oil, crude oil.

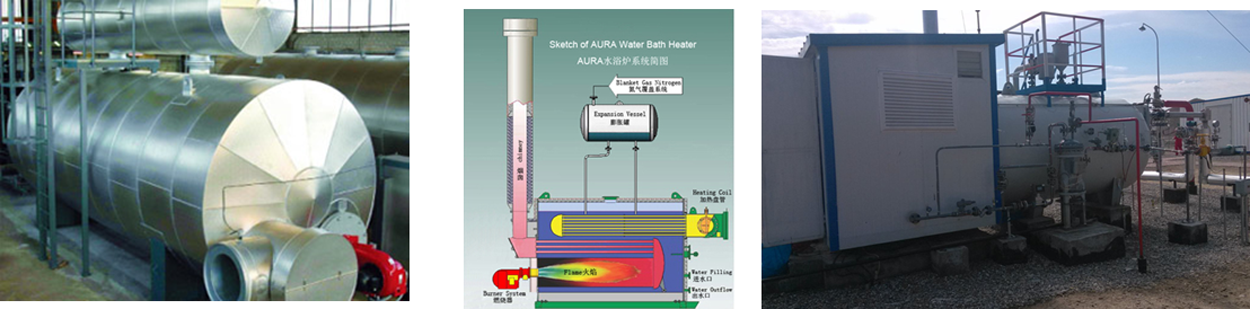

水浴炉工作原理:燃烧器将燃料充分燃烧,热量经加热炉火筒(辐射受热面)及烟管(对流受热面)传递给壳体内中间介质水,水将热量传递给浸泡其中的盘管,从而使盘管中的介质被加热

Working principle of water bath furnace: The burner fully burns the fuel, and the heat is transferred to the intermediate medium water in the shell through the heating furnace fire tube (radiation heating surface) and smoke pipe (convection heating surface). The water transfers the heat to the coil immersed in it, thereby heating the medium in the coil

2、特点:2. Characteristics:

水浴炉采用户外设计,全天候防护。The water bath adopts an outdoor design with all-weather protection.

水浴炉无压运行,无锅炉安装要求,无排放,无相关锅炉规范和操作约束;The water bath operates without pressure, there are no boiler installation requirements, no emissions, and no relevant boiler specifications and operational constraints;

水浴式加热炉组由二部分组成:炉体、换热器。炉体上部分设有膨胀水箱。换热器严格按照国家标准GB151-1999管壳式换热器制造。间接式加热:本体无压、系统承压,标准配置出口压力1.0Mpa.主要由水套、火筒、烟管、烟囱、盘管、燃气燃烧控制系统组成及操作间组成,设备出厂时所有附件仪表全部安装完毕,经过近二十年的油田现场应用及设计优化,具有性能极其可靠,热效率高,安装使用简单等优点。

The water bath heating furnace group consists of two parts: the furnace body and the heat exchanger. The upper part of the furnace is equipped with an expansion water tank. The heat exchanger is manufactured strictly in accordance with the national standard GB151-1999 for shell and tube heat exchangers. Indirect heating: The main body has no pressure, the system is pressurized, and the standard outlet pressure is 1.0Mpa. It mainly consists of a water jacket, a fire tube, a smoke pipe, a chimney, a coil, a gas combustion control system, and an operating room. All accessory instruments are installed when the equipment leaves the factory. After nearly 20 years of on-site application and design optimization in oil fields, it has the advantages of extremely reliable performance, high thermal efficiency, and simple installation and use.

A、产品主要性能特点: A、 Main performance characteristics of the product

1、针对用户需求个性化设计,提供油气田及集输系统介质加热的完善解决方案;只要用户提供相关的技术参数和要求,即可为用户量身定制并提供完美的周到、可靠的服务。

1. Personalized design tailored to user needs, providing comprehensive solutions for medium heating in oil and gas fields and gathering and transportation systems; As long as users provide relevant technical parameters and requirements, we can tailor and provide perfect, thoughtful, and reliable services for them.

2、适应范围广,被加热介质可以是天然气、原油、污水以及混合井流物。处理量范围大,管程压力可达7MPa。

2. Widely applicable, the heated medium can be natural gas, crude oil, sewage, and mixed well fluids. The processing capacity range is large, and the tube side pressure can reach 7MPa.

3、加热性能稳定、均匀;控制最佳风燃比,燃烧效率高。

3. Stable and uniform heating performance; Control the optimal air-fuel ratio for high combustion efficiency.

4、单盘管、多盘管设置,各盘管负荷和管程压力依照用户要求设计。

4. Single coil and multi coil settings, with each coil load and tube side pressure designed according to user requirements.

5、盘管可以是可抽出式,易于维修和保养。5. The coil can be withdrawable and easy to maintain and repair.

6、一体化撬装设计、结构紧凑,热效率高,按装简单、维护方便。

5. Integrated modular design, compact structure, high thermal efficiency, simple installation, and easy maintenance.

7、丰富冗余的全自动控制系统,实现输出功率自动调节、安全防护及故障应急手动等功能;独立、稳定的控制系统实现上传和接受外围控制系统信号和指令,实现了真正意义上的全参量控制。

6. Rich and redundant fully automatic control system, realizing functions such as automatic output power adjustment, safety protection, and emergency manual fault response; An independent and stable control system enables uploading and receiving signals and instructions from peripheral control systems, achieving true full parameter control.

8、无电负压燃烧型设备可以在无电源环境中正常工作及自我控制盒故障保护,性能可靠,故障率极低。

7. The non electric negative pressure combustion type equipment can work normally in a non power environment and has self-control box fault protection, with reliable performance and extremely low failure rate.

9、全自动微电脑控制,安全可靠,机组配有微电脑控制系统,实现燃烧、水位、温度自动控制,确保机组安全可靠运行。

9. Fully automatic microcomputer control, safe and reliable. The unit is equipped with a microcomputer control system to achieve automatic control of combustion, water level, and temperature, ensuring safe and reliable operation of the unit.

10、使用寿命长,机组内 热媒水,在90℃以下低温运行,并完全排除了溶解氧的腐蚀,换热器中不结垢,延长了机组使用的寿命,换热效果极佳,是普通锅炉寿命1.5~2倍,长达20年。

10. Long service life, the heat medium water in the unit operates at low temperatures below 90 ℃ and completely eliminates the corrosion of dissolved oxygen. The heat exchanger does not scale, extending the service life of the unit. The heat transfer effect is excellent, 1.5 to 2 times the service life of ordinary boilers, up to 20 years.

11、结构紧凑、安装简便、节省费用 锅炉与换热器的一体化设计,结构紧凑,产品易于运输、安装。多台机组并联使用,免去了换热站的设计与施工,节省费用。

11. The integrated design of the boiler and heat exchanger is compact in structure, easy to install, and cost-effective. The product is easy to transport and install. Multiple units are used in parallel, eliminating the need for design and construction of heat exchange stations and saving costs.

本公司拥有各类专业技术人员,实力雄厚,并建立有完善的服务体系, 可为用户提供“一条龙”式的一流服务:从设计、安装、调试到保养、维修等,亦可按用户的不同要求而提供不同形式的单项或多项服务。

Our company has various professional and technical personnel with strong capabilities, and has established a complete service system, which can provide users with a "one-stop" first-class service: from design, installation, commissioning to maintenance, repair, etc. We can also provide different forms of single or multiple services according to users' different requirements

中国常州市上能锅炉有限公司联系方式

Contact information of Changzhou Shangneng Boiler Co., Ltd., China

联系人:芮亚平

Contact person: Rui Yaping

手机:+8613815029577

Mobile:+8613815029577

微信号:13815029577

WeChat ID: 13815029577

邮箱:czjnguolu@163.com

Email: czjnguolu@163.com

工厂地址:常州市新北区黄河西路与尚德路交叉路口向南160米处

Factory address: 160 meters south of the intersection of Huanghe West Road and Shangde Road in Xinbei District, Changzhou City

开户行:中国工商银行常州钟楼支行

Opening Bank: Industrial and Commercial Bank of China Changzhou Zhonglou Branch

美元帐号:1105020509714031781

USD account: 1105020509714031781